ΠΡΟΣΦΟΡΕΣ

Spray guns

12,40 €

Kit βελόνας SAGOLA DEFYNIK 10011108 NEEDLE NOZZLE KIT 2.2MM.

Spray guns

Kit βελόνας SAGOLA DEFYNIK 1.6MM

12,40 €

Kit βελόνας SAGOLA DEFYNIK 20010121 NEEDLE NOZZLE KIT 1.60X

lot 50.843.

Κομπρεσέρ Αέρος

Ρυθμιστής αέρα πιστολιού βαφής

31,00 €

Yψηλής ποιότητας ρυθμιστής & διαχωριστή νερού λαδιού πεπιεσμένου αέρα με μανόμετρο. Έχει σχεδιαστεί για να αντέχει σε οποιοδήποτε περιβάλλον εργασίας.

62,00 €

Το H2 No. 1 είναι ένα πρακτικό σύστημα αρμολόγησης, γεμίσματος κενών σε πέτρα, πλάκα, πόρτες κτλ. Γεμίζει εύκολα ο θάλαμος στο εσωτερικό του με κονίαμα και στη συνέχεια γεμίζονται εύκολα τα κενά.

99,20 €

Το πιστόλι V77P εφαρμόζει σε αντλίες χαμηλής πιέσεως HVLP και είναι ιδανικό για βαφή και φινίρισμα.

Συστήματα Αμμοβολής

Πιστόλι αμμοβολής SBG

124,00 €

Πιστόλι αμμοβολής SBG με λάστιχο αναρρόφησης - λειτουργεί με κομπρεσέρ αέρος.

Θέρμανση Υλικών

Ζώνη θέρμανσης δοχείου 30lt

168,00 €

248,00 €

Ζώνη θέρμανσης υλικών για υλικά με υψηλού ιξώδες όπου δεν συνιστάτε μεγάλη ή καθόλου αραίωση.

Pressure tanks HVLP

Δοχείο πιέσεως 10λτ με πιστόλι βαφής

248,00 €

Δοχείο πίεσης 10 λίτρων κατάλληλο για παχύρρευστα υλικά όπως κόλλες, εποξειδικά, πολυουρεθανικά κτλ. Μπορεί να ψεκάσει και κονιάματα με κοκκομετρία έως 1mm

248,00 €

To ES 345 είναι ένα πιστόλι βαφής βαρέος τύπου, ελαφρύ και εύχρηστο, 345 bar ιδανικό για ψεκασμό υλικών με υψηλό ιξώδες.

285,20 €

Devilbiss Advanced HD Conventional πιστόλι βαφής μαζί με Δοχείο πιέσεως 2 λίτρων 230€ + ΦΠΑ !! Επαγγελματικό πιστόλι υψηλής ποιότητας και βαφής από την παγκόσμια εταιρεία Devilbiss.

Πιστόλια - παρελκόμενα

Προέκταση με γωνία 45°

296,00 €

496,00 €

Προέκταση 1 μέτρο με γωνία 45° για όλα τα πιστόλια EUROMAIR

Πιστόλια βαφής (χειρός)

Devilbiss CSPRAY Feed

322,40 €

Το εξειδικευμένο πιστόλι για την ναυτιλία BLACK ΠΡΟΣΦΟΡΑ 320€ + ΦΠΑ με μπεκ 1,2mm !!

372,00 €

Λειαντήρας σοβά με ισχυρό μοτέρ 710W και διαμέτρους δίσκου 390mm.

Ιδανικό για εργασίες φινιρίσματος, με το καλύτερο αποτελέσματα στην επιφάνεια σοβά, στόκου ή για λείανση σε άγριες επιφάνειες.

Η τιμή περιλαμβάνει :ένας πλαστικός δίσκος, ένα σφουγγάρι λείανσης, 3 δίσκοι γυαλόχαρτο, ένα ζευγάρι καρβουνάκια μοτέρ, ένας φακός και ένα διπλό κατσαβίδι.

Κομπρεσέρ Αέρος

Walcom PRF Filter

372,00 €

Φίλτρο αέρα Walcom PRF Filter με ρυθμιστής πίεσης, μανόμετρο και 2 βάνες αέρα. Ιδανικό για φούρνο βαφής, αεροσυμπιεστές, πιστόλια βαφής για εξαιρετικό φιλτράρισμα αέρα!!

372,00 €

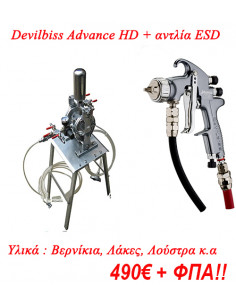

Υψηλής ποιότητας, ανατομική χειρολαβή, ελαφρύ και φιλικό στον χρήστη το Advance HD.

483,60 €

Υψηλής ποιότητας, ανατομική χειρολαβή, ελαφρύ και φιλικό στον χρήστη το Advance HD.

Συστήματα βαφής χαμηλής πίεσης

Συσκευή καθαρισμού πιστολιών

496,00 €

Μια καινοτόμα επαγγελματική συσκευή για τον καθαρισμό πιστολιών airless και χειρός. Η καμπίνα καθαρισμού PWS 700i είναι για εσωτερικό καθαρισμό - πλύσιμο πιστολιών αντλιών χωρίς αέρα airless, πιστόλια ψεκασμού κ.α αλλά και μπέκ.

558,00 €

Προσφορά Boyiair 2050 κομπρεσέρ αέρος + ES-HVLP pack πιστόλια βαφής σε πρακτικό βαλιτσάκι. O αεροσυμπιεστής Boyiair είναι σχεδιασμένοw για καθημερινή επαγγελματική χρήση σε όλους τους τύπους εργασίας. Τοποθετημένο πάνω σε εργονομική βάση με τροχούς. Μικρός σε όγκο κατάλληλος για συνεχόμενη παροχή αέρα έως 250 λίτρα / λεπτό.

Pressure tanks HVLP

DeVilbiss KBII 2,3L δοχείο πιέσεως

599,00 €

Δοχείο 2,3 λίτρων πιέσεως κατάλληλο για σύνδεση με πιστόλια χωρίς δοχείο για πολύ λεπτό φινίρισμα, βαφή, λάκες, λούστρα κτλ αλλά και για ενέσιμα υλικά. Η τιμή περιλαμβάνει εύκαμπτο λάστιχο υλικού και αέρα.

607,60 €

Αντλία ESD 10 & Devilbiss Advanced HD Trans-Tech.

930,00 €

Το Airless Spray ES 200 είναι μία μικρή πολύ ισχυρή και πρακτική λύση, κατάλληλο για τον ψεκασμό προϊόντων που χρησιμοποιούνται σε κτήρια, μεταλλικές κατασκευές, ξυλουργεία κ.α με ρυθμιζόμενη πίεση από 0 bar έως και 200 bar. Οικονομικό για μικρό σε όγκο εργασίες.

3.340,00 €

4.340,00 €

BINKS airless MX LITE 12/32 είναι μία αεροκίνητη αντλία ιδανική για βιομηχανικές, βιοτεχνίες και μονάδες παραγωγής. Μπορεί να ψεκάσει υλικά με χαμηλό έως και υψηλό ιξώδες με πίεση έως και 256 bar με σταθερή ροή πίεσης (χωρίς παλμό) επιτυγχάνοντας τη τέλεια βαφή. Κατανάλωση αέρα ΜΟΝΟ 250 λίτρα/λεπτό !!

Αεροκίνητες αντλίες Airless

ES-PN66 αεροκίνητο airless

3.707,60 €

Το ES-PN66 airless είναι μία αεροκίνητη αντλία ιδανική για βιομηχανίες, βιοτεχνίες και μονάδες παραγωγής - βαφής ξύλου, μετάλλου, σκαφών κτλ. Μπορεί να ψεκάσει υλικά με χαμηλό έως και υψηλό ιξώδες με πίεση έως και 530 bar με σταθερή ροή πίεσης (χωρίς παλμό) επιτυγχάνοντας τη τέλεια βαφή.

Μηχανήματα κονιαμάτων

ESP 3600 PLUS Αντλία κονιαμάτων

3.968,00 €

Το ESP 3600 PLUS είναι μια αντλία έτοιμων κονιαμάτων με αεροσυμπιεστή μικρή σε όγκο με παροχή υλικού 12 λίτρα/λεπτό! Ιδανικό για ψεκασμό υλικών με χαμηλό έως και υψηλό ιξώδες με κοκκομετρία έως 3 mm.

4.340,00 €

Το ES-H9000 είναι ένα μονοφασικό υδραυλικό εμβολοφόρο airless βαριάς επαγγελματικής χρήσης στις πιο δύσκολες συνθήκες. Είναι σχεδιασμένο για ψεκασμό όλων των υλικών με βάση το νερό ή διαλύτη στον τομέα των κατασκευών, βιομηχανίας, ναυτιλίας κ.α.

Χάρη στην άμεση αναρρόφηση υλικού από το δοχείο, το ES-9000 είναι σε θέση να ψεκάζει προϊόντα με υψηλό ιξώδες !!

Μηχανήματα Πολυουρίας & Αφρού

ES-PU15 μηχάνημα αφρού πολυουρεθάνης & πολυουρίας

24.180,00 €

Το ES-PU15 είναι το ΝΕΟ και μοναδικό στη κατηγορία του στην καλύτερη τιμή της αγοράς! Πολύ δυνατό υδραυλικό εμβολοφόρο μηχάνημα αφρού πολυουρεθάνης & πολυουρίας στη παγκόσμια αγορά! Πολύ εύκολο στη χρήση με εύκολη μεταφορά. Εύκολη πρόσβαση σε όλους τους χώρους εργασίας με μέγιστο λάστιχο υλικών έως 93m. Συνολική ισχύς 17kW ώστε να λειτουργεί με γεννήτρια...

Η εταιρεία

Οι υπηρεσίες μας

Σωστή καθοδήγηση για την επιλογή των πιο αξιόπιστων λύσεων ροής και ψεκασμού σύμφωνα με τις ανάγκες σας.

Σας κατευθύνουμε στη σωστή χρήση του μηχανήματος που αγοράζετε με οδηγίες και βίντεο σε Ελληνικά και Αγγλικά.

Υποστήριξη μέσω επίδειξης - σεμιναρίου, βιντεοκλήσης ή τηλεφωνικής συνομιλίας.

Σέρβις, συντήρηση και ανακατασκευή επαγγελματικών μηχανημάτων.

Ανταλλακτικά για μηχανήματα airless, μηχανήματα πολυουρίας - πολυουρεθάνης και κονιαμάτων.

Παρέχουμε τεχνογνωσία για τον ψεκασμό, την αρμολόγηση και τα ενέματα.

Έχουμε εφεύρει μοναδικά συστήματα για παγκόσμιες εταιρίες και μεγάλα κατασκευαστικά έργα στην Ελλάδα.

Επί του έργου

1. Εξειδίκευση

2. Γνώση

3. Τεχνική υποστήριξη

4. Επαγγελματισμός

5. Παγκόσμιες καινοτομίες